Greater toolpath control is achieved with the new cut increment and Z-offset modifiers. The new release significantly enhances the existing EDGECAM chamfering cycle with five new pieces of functionality, which are similar to those already found in the profiling cycle. If the undercut angle is too big, it can be compensated for by using the maximum overhang angle, effectively over-ruling the angle on the part.”Īdditionally, further boundary control options have been included, which mimic the same functionality of other milling cycles, allowing for greater material displacement control. Product Manager John Buehler says, “This is necessary because different materials and processes require different negative material build-up, depending on the target shape. It also delivers a fresh new look and feel for the ‘auto-constrained surface’ command, used to quickly create complex surfaces.ĮDGECAM 2020.1 enhances the additive lace cycle’s ‘undercut’ function by allowing the user to set a maximum overhang angle. EDGECAM reads this information and applies it to the features, so it can be used in strategy decisions, or to set speed and feed rates.Īdditionally, this latest version offers the powerful new ‘edit boundary’ command for modifying the trimming of faces directly on a sheet or solid body without having to extract any surfaces or edges.

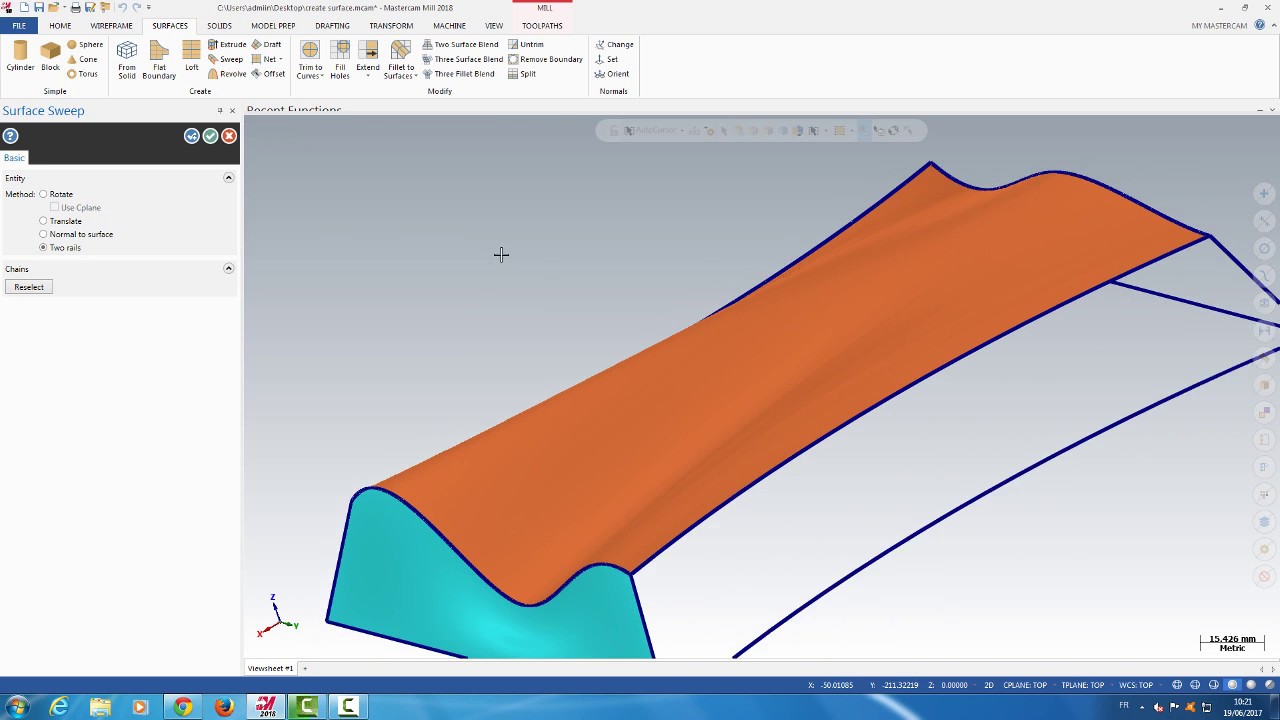

More than 50 enhancements have been made to Designer, including the ability to attach finishing and tolerance information to models and faces with the new ‘surface attributes’ command. From model design to part repair and modification, EDGECAM Designer is said to be the ultimate solution for taking geometry through to manufacture. You simply want to adjust the tool length so that the holder clears the part.The latest release of EDGECAM features toolpath associativity for the face mill cycle, the option to extend the solution’s parallel lace toolpath, enhanced additive undercutting, and a total of about 30 updates.Īlongside the new EDGECAM 2020.1, the optional CAD for CAM Designer module has now replaced Part Modeler. This is a great utility to use when you don’t want to modify the toolpath for example, trimming it to avoid collisions. “Or I can tell the check holder utility to do that edit automatically. “I can take that information, edit the operation, and have confidence I’m not going to gouge,” he continues. Where the calculation finds an interference between holder and part, the utility will suggest a longer tool stick-out length. One is Check Holder, which “calculates a safe, minimum tool projection for mill toolpaths,” says Conigliaro. And it tends not to create noise in the toolpaths.” According to company officials, Equal Scallop produces a superior surface finish compared to previous Mastercam high-speed toolpath function, specifically 3D HST Scallop.Ĭheck Holder: Mastercam 2019 incorporates several capabilities previously available as add-ins. It’s less likely to create wavy motion, which is pretty common in scallop toolpaths across the industry.

#Mastercam 2019 undercut surfaces software#

Equal Scallop, says Dave Conigliaro, CNC Software mill product line manager, “is not an incremental improvement this is completely different. That probe path exists effectively as a tool path within your NC program.” Both tool and probe paths can be post-processed with a modified postprocessor, then transferred together-despite their separate functions-to the machine tool.Įqual Scallop: A new 3D high-speed toolpath, Equal Scallop, creates a consistent scallop motion relative to stepover distance. You can import a curve, sketch a curve onto the model, extract a curve from the model as well. With 2019.1, continues Perry, programmers can “create a probe tool, nice and simple, create a stylus, the probe body, etc. PowerMill now includes the best parts of PowerInspect. Instead, PowerMill users had to turn to other products for probing, such as Autodesk PowerInspect. Probing: “Probing inside CAM software is not revolutionary, but PowerMill has not had probing at all, ever,” says Perry. This bit of automation replaces having to remember for every toolpath which clamps to ignore or check for collisions. These clamps can be associated with specific setups, even if the clamps are not in place at the start of the machining operation. Also, “a new ‘clamp’ entity allows programmers to quickly define whether to ignore a fixture or collision check against it during toolpath calculation,” says Perry, as well as assign clearance requirements and collision parameters.

0 kommentar(er)

0 kommentar(er)